You must be able to demonstrate continual improvement. Most auditors would expect you to revise the health and safety management system documentation and processes as the management system matures or when a new process is implemented.

Contents

- What is Continual Improvement for ISO 45001?

- How to Identify Areas for Continuous Improvement

- Implement a Process

- Inputs to Continual Improvement

- Requirements for Continual Improvement Interrelate With Clauses

- Aim of a Continual Improvement Programme

- Meeting Customer Requirements

- Continual Improvement PDCA

- Non-conformity and Corrective Action Procedure [Template download]

Determine whether your organization identifies improvement opportunities and OH&S Management System underperformance using the data output from its processes, such as from analysis and evaluation, internal auditing, management review, and the use of appropriate tools and methodologies to support validate findings.

Ensure that your organization has implemented the identified opportunities for improvement in a controlled manner.

You should seek objective that your organization has implemented a process, with appropriate methods, techniques, and formats for identifying areas of underperformance or opportunities for improvement.

You should expect to evidence that your organization has selected the appropriate tools and techniques to investigate the causes and thereby establishing and implementing a process for continual improvement.

Our Nonconformity & Corrective Action Procedure is proven to work.

The impetus for continual improvement must come from the use of (as a minimum):

Processes can always be made more efficient and effective, even when they are producing conforming products.

The aim of a continual improvement programme is to increase the odds of satisfying customers by identifying areas that need improvement. It requires the organization to plan improvement systems and to take into account many other activities that can be used in the improvement process.

You will be required to ensure that you continually improve the degree to which your products and services meet customer requirements and to measure effectiveness of your processes.

To this end the continual improvement principle implies that you should adopt the attitude that improvement is always possible and your organizations should develop the skills and tools necessary to drive improvement.

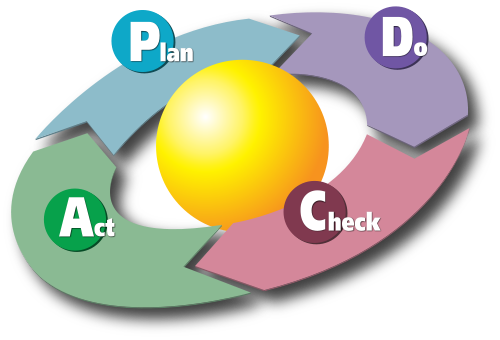

The PDCA cycle is a perfect way of introducing continual improvement to your organization’s activities. Each step to improvement can be defined by four sub steps, Plan, Do, Check and Act:

1. Plan: Establish a timetable for internal audits and management reviews. Establish the objectives and processes necessary to deliver results in accordance with your customer’s requirements and your organization’s policies.

2. Do: Implement changes designed to solve the problems on a small scale first to see the effect. This minimizes disruption to routine activity while testing whether the changes will work or not.

3. Check: Monitor and measure processes and product against policies, objectives and requirements and report the results. Also check on key activities to ensure that the output is conforming and not influenced by the changes.

4. Act: Take actions to continually improve process performance. Implement the changes on a larger scale, if the experimental changes have proven to be successful. This means making the changes a routine part of the activity.

Also act to involve other people, departments or suppliers affected by the changes and whose co-operation is needed to implement them on a larger scale. Make sure that changes are documented properly according to the documentation requirements.

Updated: 30th April 2022

Author: Richard Keen

Richard is our Compliance Director, responsible for content & product development.

But most importantly he is ISO's biggest fanboy and a true evangelist of the standards.

Learn more about Richard

Don’t Try to Manage It All Alone!

Our ISO Auditors and Quality Manager Trainers have been in this industry for years, and since 2002 we’ve been providing thousands of small businesses and large corporations with the tools they need to get certified.

Instead of trying to create everything you need to follow this process from scratch, use ours. We have procedures, templates, checklists, process maps, forms and gap analysis tools to help you control your documented information without missing a single input or output.

Before you invest all the hours reinventing the wheel, before you spend countless dollars outsourcing the task — try our templates.

| QMS ISO 9001 |

EMS ISO 14001 |

OH&S ISO 45001 |

|

Nonconformity & Corrective Action Procedure The purpose of this procedure is to establish the process for identifying, documenting and analyzing nonconformities and mitigating their impacts by implementing appropriate corrective actions. Your organization’s quality management system is geared toward the proactive elimination of actual and potential deficiencies. Nonconformities in products, services, processes and our management system are investigated and action implemented to prevent their occurrence. Forms & Reports also included:

> FREE DOWNLOAD - Control of Calibrated Equipment Procedure - this will give you a good idea of what to expect when you purchase the procedure. |

$19 USD |

$19 USD |

$19 USD |

ISO 9001 + ISO 14001 IMS Corrective Action Template

Everything you need to prepare for, manage and tighten up your Corrective Action documentation. |

$35 USD |

||

ISO 9001 + ISO 45001 IMS Corrective Action Template

Everything you need to prepare for, manage and tighten up your Corrective Action documentation. |

$35 USD |

$35 USD |

|

ISO 9001 + ISO 14001 + ISO 45001 IMS Corrective Action Template

Everything you need to prepare for, manage and tighten up your Corrective Action documentation. |

$35 USD |

||

Pay by Credit Card, Debit Card, PayPal or Apple Pay.

|

Please read our Money Back Guarantee. |

Bought by Small Businesses and Large Corporations our templates have been sold online and CD since 2002.

Used by:

The Templates are used by first-timers following our step-by-step, clause-by-clause guidance documents; and experienced Quality Managers wishing to streamline and improve their existing documentation.

The application of our templates is scalable and generic; regardless of the size and type of organization. The elements that form the quality management system are the same.

1. Our customizable templates save you time and money by offering a streamlined process to create your quality documentation

2. They’ve got everything you need in one simple template

3. Proven to work our templates have helped thousands of businesses big and small achieve certification

4. Documents use styles to make reformatting and rebranding a breeze

5. Our templates are generalizable for any industry or sector. The application of our templates is scalable and generic; regardless of the size and type of organization.